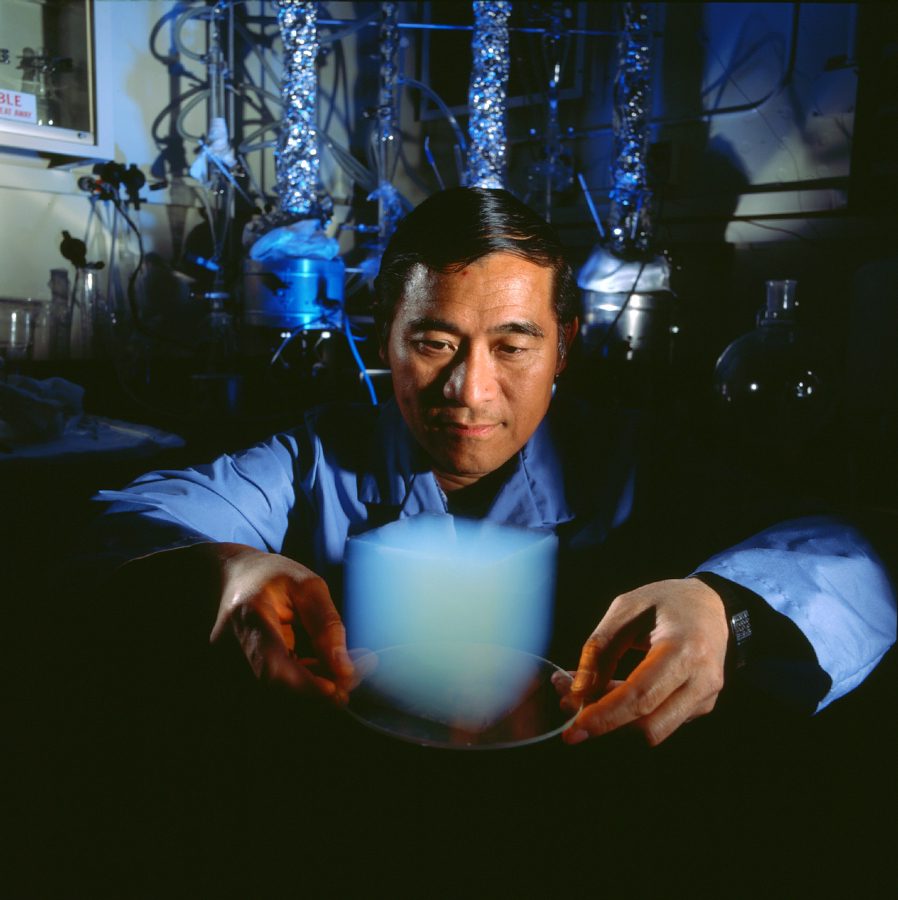

How to make Aerogel – only for crazy science people…

Aerogel starts as a silica dioxide gel, similar to the gelatine dessert you might make at home. Then the liquid in the gel is removed without collapsing the gel (normal evaporation causes the gel to collapse).

Ingredients

- Tetraethoxysilane (tetraethyl orthosilicate), Si(OC2H5)4

- Absolute (200-proof) ethanol

- Deionized water

- Ammonium hydroxide, 28-30 wt % in water

- Ammonium fluoride, NH4F

- Weigh 1.852 g NH4F and add it to 100 mL of water. Add 20.50 g (22.78 mL) ammonium hydroxide solution. Store this in a bottle so you can reuse it later. This is the “ammonium fluoride/ammonium hydroxide stock solution”. If you already have stock solution prepared you can skip down to step 2.

- Mix 4.7 g (5.0 mL) TEOS and 8.68 g (11.0 mL) ethanol in a beaker. This is the “alkoxide solution”.

- Mix 7.0 g (7.0 mL) water and 8.68 g (11.0 mL) ethanol in another beaker. Add 0.364 g (0.371 mL, ~8-10 drops from a disposable pipette) of ammonium fluoride/ammonium hydroxide stock solution. This mixture is the “catalyst solution”.

- Pour the catalyst solution into the alkoxide solution and stir. This is the “sol”.

- Pour the sol into molds and allow gel to form. Gel time is approximately 8-15 min.

TEOS is the source of the silica. Water is what hydrolyzes the TEOS so that it can polymerize. Ethanol is a co-solvent that is miscible with both TEOS and water to get both into the same phase so they can react. Ammonium hydroxide is a basic (alkaline) catalyst that helps to make the reactions go faster. Fluoride ion is a catalyst that helps hydrolysis happen more quickly.

Next steps

Supercritical Drying

The final, and most important, process in making silica aerogels is supercritical drying. This is where the liquid within the gel is removed, leaving only the linked silica network. The process can be performed by venting the ethanol above its critical point (high temperature -very dangerous) or by prior solvent exchange with CO2 followed by supercritical venting (lower temperatures -less dangerous). It is imperative that this process only be performed in an autoclave specially designed for this purpose.

- Once the gel has set, place it under ethanol and allow the gel to age for at least 24 h.

- Exchange into 200-proof ethanol or acetone at least four times over the course of several days to a week.

- Supercritically dry. A suggested procedure would be to heat the CO2 through its critical point (31.1°C and 72.9 bars) to ~45°C while maintaining a pressure of ~100 bars. Depressurize at a rate of ~7 bar h-1.

This will produce an aerogel with a density of approx. 0.04 g cm-3.

– Mike Rothman (with help from the Aerogel community)